After treating the steel at a temperature of 1075 or higher it will become softer than in the annealed form.

17 4 stainless steel condition h1025.

Rockwell c 38 average condition h1150 1150 f for 4 hours air cool.

H900 480 c 1 air 420 44 h925 495 c 4 air 409 42 h1025 550 c 4 air 352 38 h1075 580 c 4 air 341 36.

Steel grades17 4ph chemical information mechanical properties physical properties mechanical properties heat treatment and micro structure temperat ure time brinell rockwell c a 1038 c 1 2 oil air to below 32 c 363 max.

In european standard the equivalent material is referred as x5crnicunb16 4 type steel.

In din standard the equivalent material is referred as 1 4542 type steel.

Cobalt is reported in the chemistry.

Equivalent materials of 17 4 h1025 stainless steels.

Stainless steel 17 4 h1025 is a precipitation hardening martensitic stainless steel which has corrosion resistance comparable to austenitic varieties.

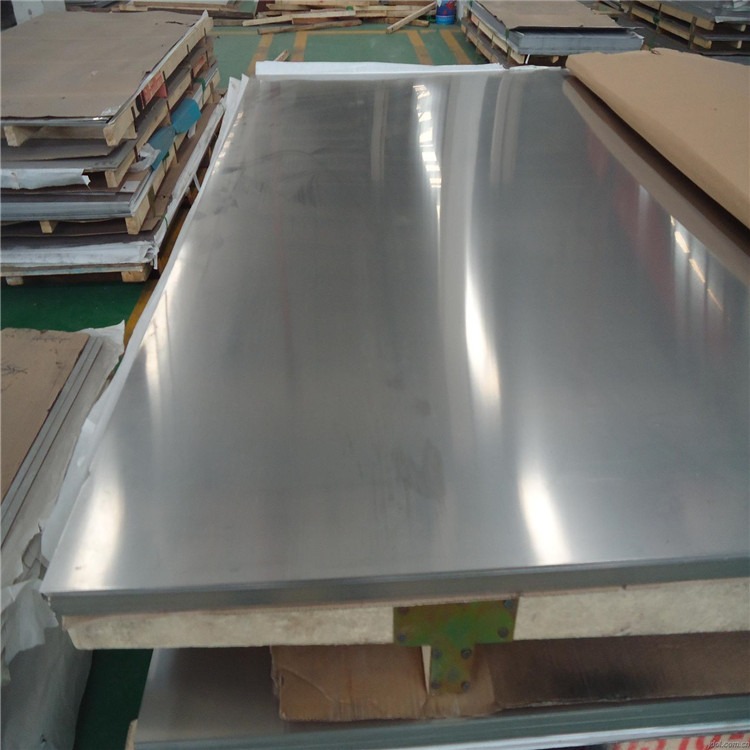

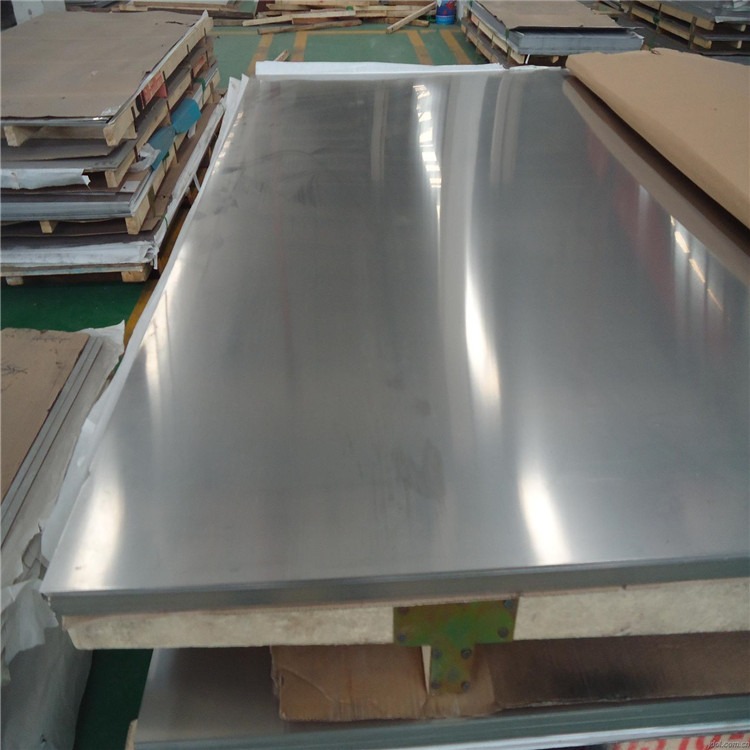

Sandmeyer steel company stocks a large inventory of 17 4ph stainless steel plate in the annealed condition in thicknesses from 3 16 through 3 ready to be processed and shipped to your specific requirements.

Al 17 4 precipitation hardening alloy is comparable to that of type 304 stainless steel in most media.

In gen eral the corrosion resistance of al 17 4 alloy is supe rior to that of the hardenable 400 series stainless steels.

17 4 stainless steel bar 17 4ph cres condition a round bar supplier tw metals.

Stainless steel 17 4 h1075 is stainless steel grade 17 4 also known as 630 alloy that has been heat treated at a temperature between 1065 f and 1085 f for 3 75 hours to 4 25 hours.

As with other precipitation hardening alloys al 17 4 pre cipitation hardening alloy is more susceptible to stress.

Condition h1025 1025 f for 4 hours air cool.

Home resources product information stainless grades precipitation hardening grades 17 4ph h1025 17 4ph h1025 penn stainless inventory now includes alloy 17 4 h1025 uns s17400 in sheet sheet coil plate round bar processed flat bar and tubular products.

17 4 is a chromium nickel copper precipitation hardening stainless steel used for applications requiring high strength.

17 4 ph condition a.

Available thicknesses for alloy 17 4ph.